I spent the first part of the week in the Bay Area, visiting

with my parents and my oldest daughter who is now ensconced at San Jose State

University, studying animation and illustration. I was glad to spend a few

hours with her, and enjoy a slice of pie at Nation’s Giant Hamburgers in

Pleasant Hill before she needed to return to the dorms.

Sunday morning, September 21st, the trek

continued and it was back up the hill to Portola. The rain started around

Rocklin on I-80, a real curiosity since I don’t see this phenomenon in Southern

(Alta) California very often anymore. Upon arriving I was able to hang out with

my pal David Wallace, and his friend Kari. David owns the red Santa Fe caboose

on the property and they were up working on flooring for it, among other

things.

Settling into the Pullman, which I may say, was as clean as

I have ever seen it (thanks David Elems!) I enjoyed the pitter-patter on the

roof and the general tranquility that is lacking so many days back at home in Lakewood.

Monday saw the arrival of Steve Lee from Cheyenne, and Dave

Varley from the GGRM. Dave has been laboriously pouring over stress

calculations on the boiler to generate our FRA Form 4 document. I am happy to

report that he is 99.9% done! All that is lacking now are a couple of test

results on a bit of metal from the two barrel courses of the boiler. Dave is

confident that given the robust construction of the pressure vessel, we should

have no problem achieving the full 180 pounds PSI of operating pressure. We

thank Mr. Varley for sticking with this truly thankless task. We didn’t see

much of him all week unless he popped out to take a measurement or two.

|

| Kirk cleans and primes components- a never ending task! |

David Elems, Steve Habeck, Rod McClure, Charlie Spikes, and

Kirk Baer deserve our thanks for getting things switched in, lined up, cleaned

up and checked out prior to our arrival. Without them we would be spending a

day or more just getting ready to work. With their help we can hit the ground running,

and accomplish as much as we do, so thanks guys!

First thing Monday morning, our Boilermaker Norman continued

work on the replacing the rigid radial stays in the patch area of the wrapper

sheet. This requires a good deal of grinding, skill and patience. By the end of

the week he had 20 out of 25 done. Channing and Erik from former Western Pacific Steam Tug Hercules in

SF joined us early in the week. We are always happy to host them; they are full

of enthusiasm and come ready to work. The guys worked replacing flexible stay bolt

caps, assisted Dave with measurements, and began down the long road toward

replacing the branch pipe bolts in the cylinder saddles. These bolts were

wasted away due to being surrounded by wet asbestos for many years. Steve

brought with him the reconditioned safety valves, thanks for letting us cross

those off our list!

Charlie and Duane got the rear cab support bolted back up so we could mount the new cab floors that Roger fabricated, previously primered by Kirk and Dave Anderson. The effort they went through to do this task proves the axiom that it takes three times “at least” as long to replace something than it does to remove it in the first place. Thanks for sticking with it guys!

Mike Mucklin, fresh in from his tenure as an Alaska Railroad conductor, spent time polishing valve and piston rods with Hank. The end result was certain mechanical parts are starting to shine up, and the locomotive is looking more like an operational machine as opposed to a park engine. Steve also got more than a few threads cleaned up on the flexible sleeves, not too many left to go!

|

| Mike Mucklin shines up the left side piston rod. |

Unfortunately Bob Sims was not able to be with us this time

due to personal reasons, but we thank him for getting the DRGW tool car to the

point where we could use it, and return tools to a specific spot every night. This

reduces the morning confusion to a great extent. Bob is back in Portola

continuing work on the car as I write this. We also thank him again for his generosity

in the acquisition of the Metropolitan injectors for the engine.

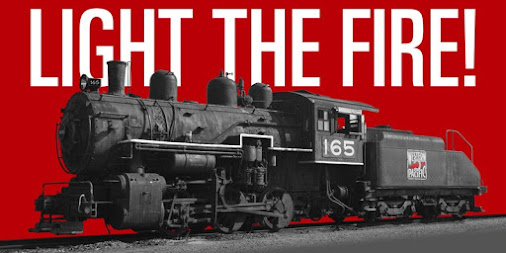

Tuesday, an authentic milestone was achieved with a

successful initial inspection of the boiler interior by the Federal Railroad Administration (FRA). This allows us to move forward with reassembly including the

tubes and flues, and puts the WP 165 back on the federal roles as a soon to be

in-service locomotive once again. This was a big weight off our shoulders, and

I am thankful to Steve Lee and Dave Varley for being on hand for the occasion.

|

| Jeff, Nancy and Ken drill out the cab top plates. |

|

| Kirk comes up for air in the firebox taking thickness readings. |

|

| Dave Varley taking measurements of the various components for the Form 4. |

|

| Erin Swain takes joy in his labor! |

Life member Erin Swain made the long journey north from

Flagstaff, AZ on Wednesday, as soon as his employer, the BNSF released him from

the bonds of servitude. Erin has been making up cab woodwork and other details,

including the side windows, and restoration by him and his dad of cab

electrical switches originally donated by Norm Holmes. Working long hours, he

got the lower portion of the cab steel replaced, as well as a new right side

drip rail on the roof. This piece of angle was prepared by Charlie, and riveted

on by Norman, Erin and Kirk prior to the cab going up in the air. A nifty

addition was a new cab hatch actuation lever fabricated by Erin, based on the

lever on the extant WP 26 at Traveltown in Los Angeles’ Griffith Park. #freeWP26

Cab Hatch Video The cab boys have a great deal to be proud of. Later, on Saturday, the cab was

reunited with the engine, and it looks great back where it belongs. Not to

mention the piece of shop floor it languished on for several years is now

available again!

|

| The drip rail is riveted on by Erin and Norman. |

|

| Mike Mucklin oversees the positioning moves. |

On the matter of the cab lift: Originally Rod McClure had planned

on using the WP derrick to lift it back into place; however, this plan was tossed

asunder when one of the engaging screws on the slew drive froze the house into

a less than desirable angular position. Lots of effort from Roger Stabler,

Channing and Erik, and David Elems failed to free up this part, so the decision

was made to use the two forklifts, which in the end proved to work just fine. Just

goes to prove that derricks need love too!

|

| Chris gets the forklift operators- Dave Elems and Rod McClure, in sync. |

|

| Back in place again! |

|

| Norman gets the air compressor bolted up while Rod looks on. |

While access was available, Steve suggested putting the air

compressor back up on the side of the boiler. After a mad scramble to find the

bolts in the parts car and clean them up, it went on with little complaint.

With parts finally going back on, the old girl is starting to look like her old

self once again!

Ken and Nancy, along with Jeff and Dave Roth from GGRM continued to drill the remaining holes on the tender deck plates. These they completed in short order, followed by reaming to allow the rivets to slip through nicely. Roger made up a makeshift rivet oven, and was able to drive one rivet but the heat was just not there. We will try again when Steve brings the oven with him next time from Cheyenne. The team of Ken, Nancy and Jeff later took on the unenviable task of cleaning the detritus out of the tender cistern. Three wheelbarrows of rust later they all looked like Umpa-Loompas, but they took it in stride, and we are now ready to sandblast in the spring. They truly embody the WP “Willing People” spirit. Hank although under the weather most of the weekend, did manage to get a couple hundred flexible stay bolt caps reconditioned and ready for use. New Teflon gaskets are now being made up at the Strasburg Railroad. These will be reapplied in the spring.

Ken and Nancy, along with Jeff and Dave Roth from GGRM continued to drill the remaining holes on the tender deck plates. These they completed in short order, followed by reaming to allow the rivets to slip through nicely. Roger made up a makeshift rivet oven, and was able to drive one rivet but the heat was just not there. We will try again when Steve brings the oven with him next time from Cheyenne. The team of Ken, Nancy and Jeff later took on the unenviable task of cleaning the detritus out of the tender cistern. Three wheelbarrows of rust later they all looked like Umpa-Loompas, but they took it in stride, and we are now ready to sandblast in the spring. They truly embody the WP “Willing People” spirit. Hank although under the weather most of the weekend, did manage to get a couple hundred flexible stay bolt caps reconditioned and ready for use. New Teflon gaskets are now being made up at the Strasburg Railroad. These will be reapplied in the spring.

After pushing the engine back in the barn on Saturday

evening, and a good amount of cleanup, it was off to Kirk and Debbie Baer’s compound

for a session of decompression on their deck. Camaraderie was the order of the

evening, as we always enjoy a change of scenery and the fellowship afforded after

the bacchanalia is over. Several Tri-tips were cooked up on Debbie’s fabulous

grill, and desserts did abound. Thanks again to our gracious hosts for putting

up with us!

In closing, 2014 provided some challenges to be sure, but in

the end the progress we made as a team was excellent. I look forward to the day

we put pressure back into the 165 boiler again, but the steps we make must be

careful and well planned for the sake of safety and practicality. We are fast approaching

the 10 year mark in this restoration, and no one is more anxious to get it done

than me, but if we remain methodical, and persistent, we will get steam up soon

enough. In the meantime, we will enjoy our journey, safely, and reach attainable

goals one by one, eventually culminating in our final goal to get the WP 165

back into the action, and I can’t think of a better bunch of folks to get it

done with! Have a happy and safe Holiday Season! -JCA

Click here for a gallery of work session photos from Mike Mucklin.

Click here for a gallery of work session photos from Mike Mucklin.

.jpg)