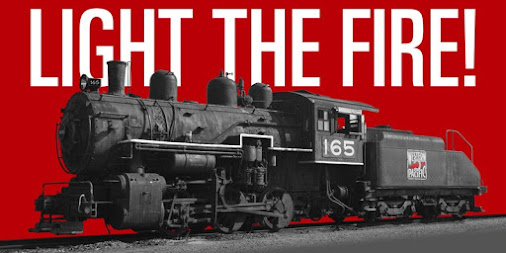

Another spring session has come to a close, and I am happy to report that a whole lot of items were crossed off the punch list this time. So many so that I will have to make up a new list!

Sunday morning, April 3rd, I left our new digs in Pine Grove and headed over Carson Pass. On the way to the WPRM I stopped into the

Nevada State Railroad Museum in Carson City and spent about an hour catching up with John Walker, the former manager at Portola. John now manages the gift shop and concessions for the NSRM. After a bit of "reminiscing" I went over to check out the recently restored

Virginia & Truckee McKeen motor car. A stunning job by Chris Dewitt and his crew.

After moving into the Pullman car for the week, I was joined by Roger Stabler, we were both happy to see that the engine was now sitting over the pit, and the tender frame was adjacent to the wood working bay. Thanks to Steve and David for getting the switching done for us!

Other tasks completed during the work week included Hank and Roger fabricating a new valve rod for the power reverse, and getting it in working order with the valve gear operating for the first time in many decades; also Roger finished up all of the problem flexible staybolt caps leaving just the 24 or so up on the roof sheet to buttoned up, once the new stays are installed.

The team of Channing, Roger, Hank and Charlie set the remaining six rivets in the firebox knuckle patch and turret drypipe bracket. These have been avoided up until now due to their awkward locations, but the guys figured out how to back them up using levers and brute force.

A big visual change to the tender came with the fitting up of the deck boards we acquired in the fall from the

Amador Sawmill Association. Charlie and Kirk have been tending to the pile of lumber, turning them every few weeks so they would dry evenly all winter, and thanks to them the boards stayed straight. Bob Sims led the effort to cut them to length, and countersink the locations where they had to sit on rivets, bolts, etc. Charlie, Lynn, Steve, Dave and Bil worked on getting them bolted down, as well as applications linseed oil to work as a preservative. Bil took it upon himself to make up the new rear footboards using some of the leftovers, and it looks great!

|

| New footboard on the rear of the tender frame. |

Dick Coudin cleaned up several components, including the handrails at the cab, and the power reverse reach-rod. Those and the handrails down both sides of the boiler have been re-applied, which adds a bit more safety for working up there. Many people remarked on how much the 165 is beginning to look like a locomotive again.

|

| Roger welds one of the cleanouts from the coal days onto the smokebox. |

Erik, our stalwart volunteer and captain of the Western Pacific tug "Hercules" suffered a bit of a hand injury right before coming up with Channing and Severn. To his credit he pushed through and was able to do a few things, like driving the forklift and plumbing up the power reverse. We hope his injury is well on the way to healing and we thank him for going above and beyond for us! Severn and Dave Roth brought up a pipe threading machine for the shop which will prove to be beyond useful to us. Thanks again

GGRM!

|

| New power reverse valve rod fabricated by Roger and Hank. |

Severn, David and yours truly spent a good amount of time standing at the lathes making studs and staybolts. This process will go well into the summer. Thanks go to Duane for wiring the 13" lathe up so it could be used. Thanks also go to David for getting the machine shop in order in time for our work session.

A veritable milestone was achieved on Thursday when Channing, Erik, Ken and Nancy began cutting the 2" tubes to length and setting them in the boiler. All in all they got almost 100 in! These will not be rolled in until later this year as we don't want the start the 15 year clock running until we are further along with the tender and a few other things.

On another front, Dave Varley delivered the completed FRA Form 4 to us, and it was signed off. Now to mail it off to Washington D.C. for review by the FRA. Dave worked like a dog on this document, which is quite thick, and the culmination of many, many hours of measuring and calculation on the part of many, including Dave. Now he can get back to moving his museum's collection over to Santa Cruz.

|

| The valve covers were removed and inspected by Hank. |

|

| The tender deck being fitted up. |

|

| Ken placing the first 2' tube back into the boiler! |

All in all another great effort from the "Steam Team". Our next big session will be in the fall, but there are lots of projects to be done before then, such as sandblasting the tender cisterns, turning stays, machining a new dome lid, and myriad other things. Brake valves have been rebuilt and tested. If we are allowed to continue at this pace we should be in steam by 2018. Fingers crossed...

More updates will come as some of these tasks get underway. Have a great spring season!

- JCA