Another season of steam restoration has come and gone, and we are getting ever closer to seeing steam return to Portola and the Western Pacific Railroad Museum. Although this year saw no big "visual" progress, a great deal was done on the inspection of the running gear, as well as turning the corner toward starting the re-assembly of the locomotive.

Dave Varley of GGRM and Steve Lee, of Cheyenne, Wyoming have dug into the FRA Form 4 calculations, and have made some headway utilizing the thickness readings obtained by Nathan Osborn and James Cowdery. Generating these numbers is a tedious undertaking to say the least, and we are very grateful to these gentlemen for taking this formidable task in hand. This document will eventually render our Maximum Authorized Working Pressure, or MAWP as it applies to our boiler.

Dick Coudin and Jeff Boone continued their work from last summer and chipped away at paint, rust, etc. on the driver center castings. These are now looking very nice in primer paint. They will look even better when they are back under the boiler and frame. This is a good example of sticking to a job until it is done, thanks guys!

Steve was also busy checking the wristpins and crankpins for cracking using our dye-penetrate kit. A red dye is sprayed on the part to be checked, wiped off, after which a "developer" is sprayed on, turning the surface white. Any cracks will be visible as red lines. Steve reported that all the components checked passed this inspection. Good news is always welcome.

|

| Steve wipes off the red dye while checking a wristpin for cracking. |

|

| The wristpins after being sprayed with the developer. The red lines are the accumulation of dye at a step in the diameters. |

Severn Edmonds, another helpful fellow from GGRM, has been rebuilding handles and other parts of our "new" lathe acquired last year from the UPRR. Duane and Charlie were able to wire it up, and Severn spent many hours cleaning and lubricating parts to make this machine shiny again. When we start threading staybolts, boiler studs and the like, it will be invaluable. Severn deserves accolades for his efforts to get this lathe back in trim, and we look forward to locomotive parts flying off as fast as he can make them!

We missed Charlie Spikes, our favorite volunteer at these workdays. His wife had recently gone through spinal surgery so he stayed home to take care of her, which we more than understand. Our thoughts are with her as well as our wish for her speedy recovery.

The "Dave's" of GGRM, Dave Roth and Dave Varley joined us for some time in the firebox. The tube ends in the rear tube sheet have been an ongoing thorn in our side, given the generous amount of seal welding around each of the 200 or so 2 inch diameter tubes, and the twenty four 4 1/2" diameter superheater flues. Dana Greeley started this project several years ago, and just about everyone in our diminutive group has had time on the angle grinder vs. the tube sheet. Dave Varley offered to tackle this as his contribution for the weekend, and we are glad he did. Between the three of them, Dave, Dave, and Severn tag-teaming with grinder, torch and hammer, over 100 of the tube ends were removed, which leaves only about 80 or so to go. Dave Varley deserves a great deal of credit for grinding for hours like a man possessed, putting the rest of us to shame! This coupled with the unseasonable warmth in Portola earned all involved a great deal of sweaty satisfaction for a job well done. Matt Parker was finally able to get in on the fun, and got many of the threads chased on the flexible staybolt sleeves before his company called him back. Great to see Matt back, it's been too long!

|

| Dave Roth demonstrates that there is no graceful way to exit a firebox. |

|

| The Daves, Roth and Varley getting things done! |

|

|

|

Saturday night the Museum management, led by Eugene Vicknair and Tom Carter put on a BBQ shindig for the workers, a great period to decompress and lick our wounds. A great end to another productive season. Thanks also to Rod and Gail McClure for running interference on many fronts, as well as their unwavering support of our project.

I would also like to thank Bob Sims for continuing the efforts on our shop boxcar. He has, at his own expense, been working on the interior, sheeting and insulating to create a nice comfortable space for working on steam components and tool storage. Bob has been working tirelessly all summer on this project, and he has our gratitude.

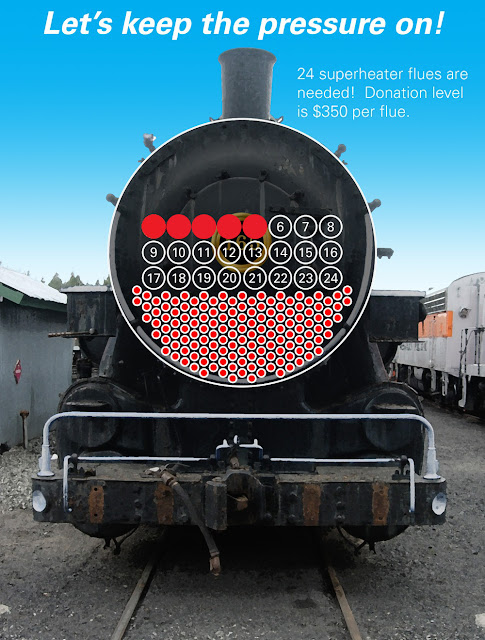

To date our superheater donors: Bob Sims, James Mason, Steve Lee and Matt Shuman, through their generosity, have seven of the 24 flues donated.

Please consider a donation, each is $350.00, is tax-deductible, and will get your name on the donors plaque in the cab. Thanks again to all of our beloved donors for your continued support!

Looking toward next year, Roger Stabler has arranged to have the locomotive's leaf springs rebuilt, These will be ready for pickup in December. The cost will be covered by Roger, which is a

very generous gesture. We look forward to getting them back in the frame in the Spring.

Speaking of Spring 2013, our next work session will be Saturday, April 20th through Saturday April 27th. This will be a full week of prep for lifting the boiler and frame back onto the drivers. With a great deal of effort, and some luck, the locomotive will be back inside by Sunday, April 28th. Severn Edmonds and Dave Varley are considering spending the week and we welcome any additional help during setup and tramming.

Sitting here writing this in the comfort of my kitchen at home, I am glad that the work session was scheduled for last week, given the gas price spike. Hopefully things will calm down soon. A small reminder that just showing up in Portola can be a great expense to our volunteers, and I certainly appreciate your diligence. I hope to get the 165 restoration "over the hump" next season, and picking up speed until we finally get a fire back in her.

Until next year, stay safe, and have an happy, healthy Holiday Season!

- JCA